About EchoRFID

PDF Brochure Download

About EchoRFID

PDF Brochure Download

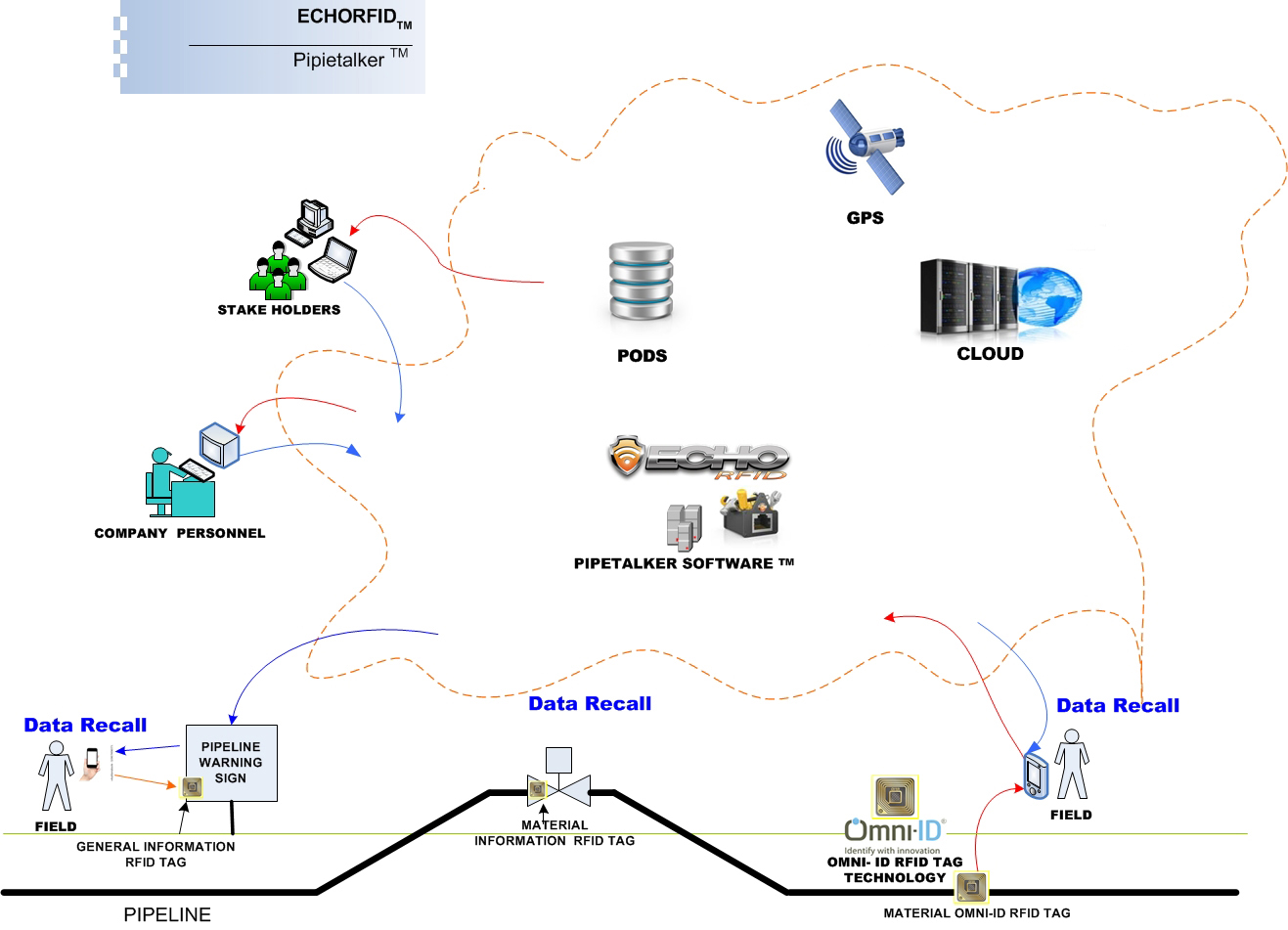

EchoRFID™ has successfully developed a system that will revolutionize how asset integrity management will be conducted in the future and provide significantly greater value to pipeline owners and operators. Through innovative Mobile, data collection, data management and RFID technologies.

EchoRFID™ understands that the mechanism to be used must provide consistency, measurability, and auditability. Consistency delivers quality. Measurability delivers assurance. Auditability delivers accountability and peace of mind. Collectively they deliver due diligence.

Mobile Technology

Mobile technology has evolved dramatically in the last five years. So much so, that it is difficult for the layperson to identify what this means, and just how it can benefit the industry. The oil and gas industry has been slow to capitalize on the vast benefits of mobile technology and still in large, depend on paper, binders, personalized PIM data sheets etc., to address data.

When mobile technology is merged with a solid integrity management system it will:

- Enhance Safety

- Create an uncomplicated link from an asset problem to the engineer assessment, through to mitigation

- The system provides a 'Living up to minute document' for integrity management

- Provide a genuine communication standard and eliminate information silos

- Greatly reduce dedicated resources required for the PIM system

- Provide data that will vastly enhance risk assessment

- Provides work units that provide and support QC and auditing

- Enable field operations to be 99% transparent and significantly more effective

- Make material and data tracking streamline and accurate

- Save millions of dollars by using materials left from other projects

- Significantly reduce a companyís liability by proving due diligence

- Provide a cradle to grave coverage of an asset

- Substantially improve the selling price of an asset

- Enable industry to lead rather than follow government agencies

- Appreciably reduce time and human resources for government agencies

- Provide industry with a new and exceptional platform when negotiating land development and projects with the private sector and government.

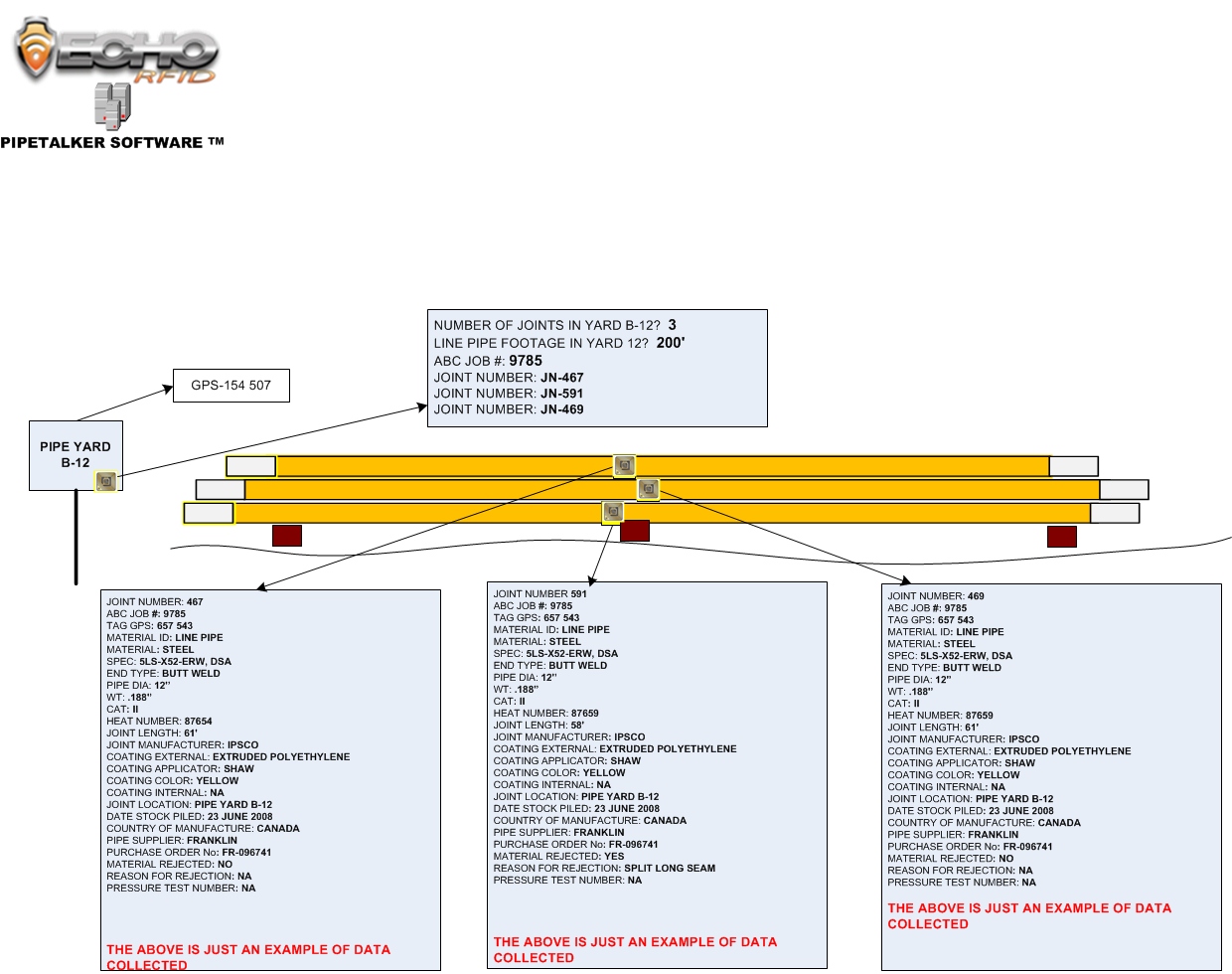

Data Collection

Industry has always known that good data on installations can reap both instant and deferred rewards, but good data is burdensome, costly, and difficult to collect and even more difficult to retrieve, share, and use. Now, because of the mobile technology advancement, this no longer has to be the case.

EchoRFID has invested three years researching, developing and entering into strategic partnerships to create the EchoRFID PIPETALKER system that we anticipate will be the new ‘standard’ in how companies approach their integrity management obligations to stakeholders, standards committees, and regulators.

Data collection starts with the design of the asset and follows the asset through construction, operation, inspection, maintenance, repair, and sale or abandonment. This is accomplished by our patented ‘modules’ that are broken down into ‘work units’. The work units are used by company personnel, third party contractors, inspectors, suppliers and manufacturers. Once a work unit is closed it, is considered an audit. Regulators may also use the system with the company’s permission, to facilitate their own audit expediently and accurately.

Data Management and Recall

Through the development of a secure data network, data repository and data management system, precise asset location based field data can be gathered and stored through RFID tags and uploaded to a data repository. With any computing device including laptops, tablets and smart phones, the precise location data and meta data (photos, video and voice) can be made available to all or selected stakeholders in real time, anytime.